Your Reservoir. Elevated.

Silverwell Intelligent Solutions enable operators worldwide to maximize recovery and reduce intervention. Our proven completions technologies adapt to every environment, optimizing conventional, unconventional, and subsea wells across key applications including Intelligent Gas Lift, Multizone Injection, and Multizone Production.

The Silverwell Approach

Whether you’re unlocking the potential of a brownfield redevelopment, optimizing a newly sanctioned greenfield, or managing flow assurance in a subsea well, Silverwell’s Intelligent Solutions evolve to meet your operational and economic priorities. From autonomous gas lift in infrastructure-light environments to full-stack zonal control in high-value wells, our modular, scalable technologies empower operators with real-time visibility and precise control, without intervention. They deliver the confidence, security, and trust you need to make better decisions with every well.

Conventional Wells

Conventional wells remain the backbone of production, but challenges such as multi-pointing, shallow injection, and frequent interventions limit recovery and increase costs. Silverwell brings intelligence to conventional completions through:

- DIAL: intelligent control and SCADA-integrated adaptability.

- Zonal monitoring, ICVs, and proactive management: extending field life and optimizing uplift.

- Real-time data and control: reducing costly interventions and improving gas allocation accuracy.

- Solutions extend across Single and Dual-String and Auto Gaslift.

With Silverwell, conventional doesn’t mean traditional. It means optimized for today and tomorrow, with Intelligent Solutions that extend field life, improve recovery, and make interventions the exception, not the rule.

Unconventional Wells

Unconventional wells decline rapidly and demand speed, agility, and data-driven adaptability. Silverwell’s solutions give operators real-time control and autonomous performance through:

- DIAL: enabling autonomous gas lift in infrastructure-light environments.

- Targeted ICVs and chemical injection: responding to frac hits, solids, and evolving well dynamics.

- Accurate gas allocation in real time: sustaining uplift while minimizing downtime.

- Solutions also include Single-String and Dual Flow.

By combining agility with intelligence, Silverwell helps operators manage decline more effectively, reduce intervention, and maximize the life of unconventional assets. Giving operators the confidence to adapt in real time.

Subsea Wells

Subsea wells carry the highest risk and cost. Silverwell provides you with intelligent completions that deliver low-power, reliable control in the harshest conditions, reducing risk and eliminating multi-million-dollar interventions. Our technologies enable:

- Continuous monitoring and real-time visibility in remote operations.

- Selective zonal production control to optimize recovery.

- Safe, reliable operation across extreme subsea conditions.

- Intelligent solutions span Single-String and Auto Gas Lift.

With Silverwell, operators gain the certainty to manage subsea wells with confidence, ensuring production security and lowering intervention costs. This is the ultimate example of how data delivers intelligence.

Intelligent Completions, Proven Worldwide

Silverwell delivers intelligent completions across conventional, unconventional, and subsea wells. Working with IOCs and NOCs globally, our technologies have delivered up to 40% uplift in production, reduced interventions, and greater certainty. From Asia to the Permian Basin to the North Sea, wherever you operate, Silverwell’s Intelligence in Reserves turns data into measurable performance.

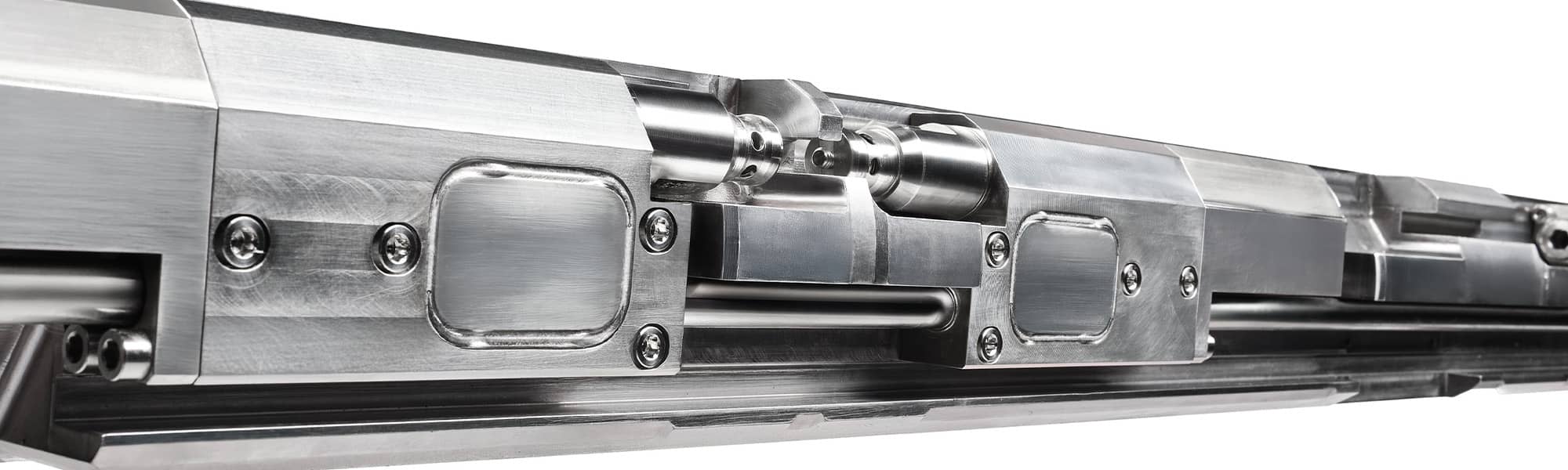

DIAL: Setting the Standard for Intelligent Completions

Our DIAL legacy technology transforms gas lift from a static system into a real-time, programmable solution. With surface or autonomous control, embedded sensing, and adaptive flow regulation, DIAL systems reduce cost, extend well life, and increase production efficiency across well types.

With Silverwell, Data

Delivers Intelligence

With agility, innovation, and relentless focus on improvement, Silverwell is redefining intelligent completions. From conventional to unconventional to subsea, we are your steadfast partner for more production with less intervention.